engineering hardness test|hardness tester for thin material : export Brinell Hardness Test (ASTM E10) Rockwell (ASTM E18) Vickers; Knoop ; Brinell v Rockwell Hardness Test Hardness Test Characteristics General characteristics of hardness-testing methods and formulas for . WEBCreditime è una Startup che offre soluzioni innovative per le aziende che si occupano di Business e Credit Management, utilizzando i dati a proprio disposizione per analizzare il .

{plog:ftitle_list}

1 de jun. de 2020 · Como Tirar Bordas Preta Do Vídeo Sony Vegas Pro 17 , Remover bordas Dos Videos Do Vegas Pro 17 [NOVO ATUALIZADO 2020]👇Meu Treinamento Completo De Edição De .

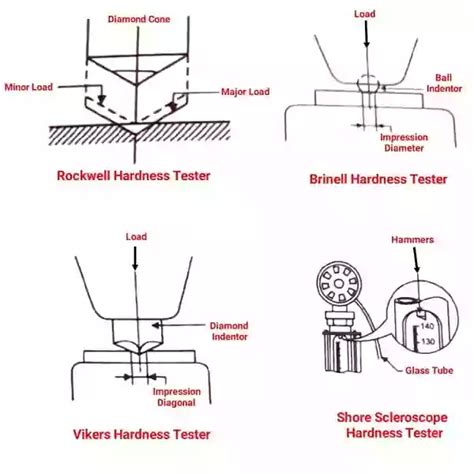

Hardness testing is an essential aid in the differentiation of materials, as well as for the analysis, development and improvement of materials and technologies within the framework of fundamental research (materials science, materials .Shore Durometer Hardness Testing: Hardness testing of polymeric materials, including plastics and rubbers, is performed by the Shore Durometer Test, according to ASTM D2240. This method determines a material’s hardness value or resistance to indentation by penetration of an indenter into the test sample. Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. . According to the engineering regulations, the ratio of F/D 2 is 30, 10 and 2.5, which are . Brinell Hardness Test (ASTM E10) Rockwell (ASTM E18) Vickers; Knoop ; Brinell v Rockwell Hardness Test Hardness Test Characteristics General characteristics of hardness-testing methods and formulas for .

There are a variety of hardness test methods in common use (e.g. Brinell, Knoop, Vickers and Rockwell). . Hardness is important from an engineering standpoint because resistance to wear by either friction or erosion by steam, oil, and water generally increases with hardness. There are three main types of hardness measurements:

In this article, we’ll get straight into the hardness in mechanical engineering, introduce different types of material hardness and common hardness scales. . The traditional indentation hardness test method is using hard indenters of defined geometries and sizes to press into the material under a particular force, and record the deformation .A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). [1] There are different scales, denoted by a single letter, that use different loads or indenters.

ROCKWELL HARDNESS TESTING The Rockwell hardness test is a fast method, making it ideal for quick hardness testing. We give a definition of the Rockwell hardness test, as well as practical information of how to apply it in practice. The Rockwell hardness test at a glance: Generally used for larger samples ; No optical readout; Can be used for .So, it is an important parameter in engineering. Hardness testing provides a means to quantify the hardness of a material, and it is a key element in many quality control procedures and R&D work. Several methods are available for hardness testing. However, Brinell, Rockwell, Vickers, Knoop, Mohs, Scleroscope, and the Files test are the most .

types of hardness testing methods

Proposed by Swedish engineer Johan August Brinell in 1900, it was the first widely used and standardised hardness test in engineering and metallurgy.The large size of indentation and possible damage to test-piece limits its usefulness. However, it also had the useful feature that the hardness value divided by two gave the approximate UTS in ksi for steels.The Rockwell hardness test method is a simple process that uses a diamond cone with a round tip for harder materials and a hardened steel ball indenter for softer ones. . The Rockwell hardness test has been compared to the Brinell test that was discovered by a Swedish engineer in 1910. In a Brinell test, a hardened steel ball under a set . Hardness generally refers to the resistance of a material to scratching or indentation, and a qualitative measure of the strength of the material. The most commonly used hardness tests are the Rockwell test, Brinell test and the Vickers hardness test. This article will provide an introduction into durometer hardness and the gauge used to .

Moh's Scale of hardness. Indentation testing. There are a number of different methods of testing the hardness of a material through indentation. The three most commonly used are the Brinell test, the Vicker’s Diamond test, and the Rockwell test. All .

The followings are the most common hardness test methods used in today`s technology: Rockwell hardness test Brinell hardness Vickers Knoop hardness Shore 3.1. Rockwell Hardness Test. The Rockwell Hardness test is a hardness measurement based on the net increase in depth of impression as a load is applied.

The hardness of a material is the property that enables it to resist deformation, bending, scratching, abrasion, or cutting. If you work in materials manufacturing, you probably already know that a hardness test is a crucial step in the production process for your products and the products you receive from third-party suppliers.The Fundamentals Of Hardness Testing In Aerospace Engineering. At the confluence of physics and engineering, hardness testing is a cornerstone of aerospace innovation. The process is foundational for determining a material’s .This article reviews the factors that have a significant effect on the selection and interpretation of results of different hardness tests, namely, Brinell, Rockwell, Vickers, and Knoop tests.Hardness testing is perhaps the simplest and the least expensive method of mechanically characterizing a material. This article provides an overview of the principles of hardness testing. It compares Brinell with Meyer hardness testing and hardness testing of fully cold worked metals with fully annealed metals.

Brinell Hardness Test. The Brinell hardness test entails measuring the diameter of indentation caused by a constant concentrated force applied by a steel or carbide spherical indenter on a test specimen. The steel ball indenter is first placed in contact with the material before a constant force is applied and maintained for a 10 to 15 second duration, known as the .DEPARTMENT OF MECHANICAL ENGINEERING MATERIAL TESTING LABORATORY I - CYCLE 1. Izod Test 2. Brinell Hardness Test 3. Shear Test 4. Bending Test II – CYCLE 5. Charpy Test 6. Rockwell Hardness Test 7. Torsion Test 8. Compression Test III– CYCLE 9. Heat Treatment 10. Tensile Test IV – CYCLE 11. Wear Test 12. Micro Structure These heat-treated samples were then tested mechanically using the Brinell hardness test (BH). . January 2001 Measuring the hardness of materials is a fundamental aspect of material science and engineering, involving various test methods each suited to specific types of materials and applications. These methods not only help in determining the hardness but also provide insights into other material properties like strength, wear resistance, and ductility.

The Leeb hardness test (LHT with test value of L D), introduced in 1975 by Dietmar Leeb (Leeb 1979), is a portable hardness tester, developed originally for measuring the strength of metallic materials, that has been adapted for prediction of σ c of rock (Kompatscher 2004).The LHT device, sometimes also referred to in the literature as the Equotip, is shown in . Mohs Hardness is more like a comparative hardness test where the material is compared for indentation against a known material or hardness value. 10 minerals are ranked on the Mohs scale from low hardness to high hardness from 1 to 10 as shown in the below picture. Mohs hardness is not suitable for engineering fields as the hardness of .Mohs hardness test: When conducting the test, place the unknown specimen on a table top and firmly hold it in place with one hand. Then place a point of the reference specimen against a flat, unmarked surface of the unknown specimen. . Center for Advanced Life Cycle Engineering, University of Maryland, last accessed August 2022. Some Notes on . Discover the critical role of rock hardness testing in geology and engineering. This article explores how assessing rock hardness aids in mineral classification, stability assessments, and resource exploration. Learn about the Mohs Hardness Scale, factors influencing hardness like mineral composition and texture, and why this knowledge is .

The Rockwell hardness test is widely used in various industrial applications, such as manufacturing, engineering, and quality control. It provides a quick and reliable measure of hardness, making it suitable for routine hardness testing on the produc-tion floor. Industrial Application The Rockwell test is particularly suitable for measuring the

Hardness is used in numerous engineering design applications. This property is essential as it directly correlates to the material’s performance and suitability. For example, a component’s resistance to wear generally increases with increasing hardness. . The Leeb rebound hardness test (LRHT) is one of the most popular methods used for .

difference between volumetric coulometric karl fischer titration service

hach titralab kf1000 series volumetric karl fischer titrator 3 980 service

18 de dez. de 2023 · This essay will explore the syllabus of a certified AI medical coder CAIMC™ course and delve into the usefulness of the course in AI medical coding. Overview of AI Medical Coding: - Definition .

engineering hardness test|hardness tester for thin material